It has always been a mystery to me whether epoxy resin and fiberglass resin are the same things, and if I had to guess, I’d say that you have the same line of thought I do.

So, let’s get down to the bottom of the matter. Epoxy resins are created mainly from the interaction between epichlorohydrin and bisphenol A. Fiberglass resins are formed from the combination of alcohols and organic acids.

The fundamental difference between these two kinds of resin is seen in this aspect. Your shopping basket sounds like it’s empty. Then, cast your imagination with the help of the finest epoxy resins for fiberglass.

Given that epoxy resin and fiberglass resin belong to the resins category, what conclusions can I draw from this information?

Before we go on to the next phase, let me explain precisely what epoxy resin and fiberglass resin are. This will prepare you for the next step in the process.

Table of Contents

1. Epoxy resin –

Epoxy resins are volatile pre-polymers and polymers that include epoxides in their structure. These resins can play catalytic homopolymerization, in which they cross-link with one another and cross-link with polyfunctional amines, acids, phenols, alcohols, and thiols.

Co-reactants are also known as cures or hardeners. Cross-linking is what is meant by “curing.” This cross-linking or curing process may make a thermosetting polymer with high mechanical, thermal, and chemical resilience.

2. Fiberglass Resin –

To create fiberglass resin, alcohols and organic acids are mixed together. There are a few different ways we can make this resin. In addition, it has the potential to solidify, liquefy, or film over.

Polyester polymers, such as those used for casting, wood filling, glue, and auto body repair, are their primary uses. Because of its high adhesiveness and durability, this substance helps bond various substrates together.

Fiberglass resins are often used to construct columns and phony ceilings. This fabric is tough and impervious to water.

In this sense, do one, and the same item refers to resin and fiberglass?

The hardener and the resin combine to produce a viscous liquid that sets into a solid state. Fiberglass Fabric is a woven cloth that contains resin that has been absorbed into it.

The fabric becomes very stiff when the resin hardens inside the fabric fibers. In the production of composite materials, the usage of fiberglass cloth is commonplace.

Fiberglass is the finished product, created from fiberglass cloth coated with resin before being woven together.

Is epoxy a more durable material than fiberglass resin?

Polyester resin(a.k.a. Fiberglass resin) is an ideal choice for the lay-up process when working with fiberglass, such as when constructing a boat.

In most cases, the tensile strength of a bond created with polyester will be about 20 percent lower than the tensile strength of an identical bond made with epoxy.

Because of this, epoxy resin is often considered the material of choice when working on repairs involving fiberglass.

Resin or fiberglass – which of these two materials do you think is the better option?

As far as the differences are concerned, there has to be a choice; thus, in this regard, fiberglass is much more long-lasting than resin.

It is far more resistant to chipping and cracking and can tolerate adverse weather conditions much better than other materials.

Because of this, the material’s adaptability may be used successfully in various settings, where the user is likely to be exposed to a wide range of environmental conditions.

Tips while working with Epoxy Resin and Fiberglass Resin –

Fiberglass Resin –

1. First, always use proper protective gear –

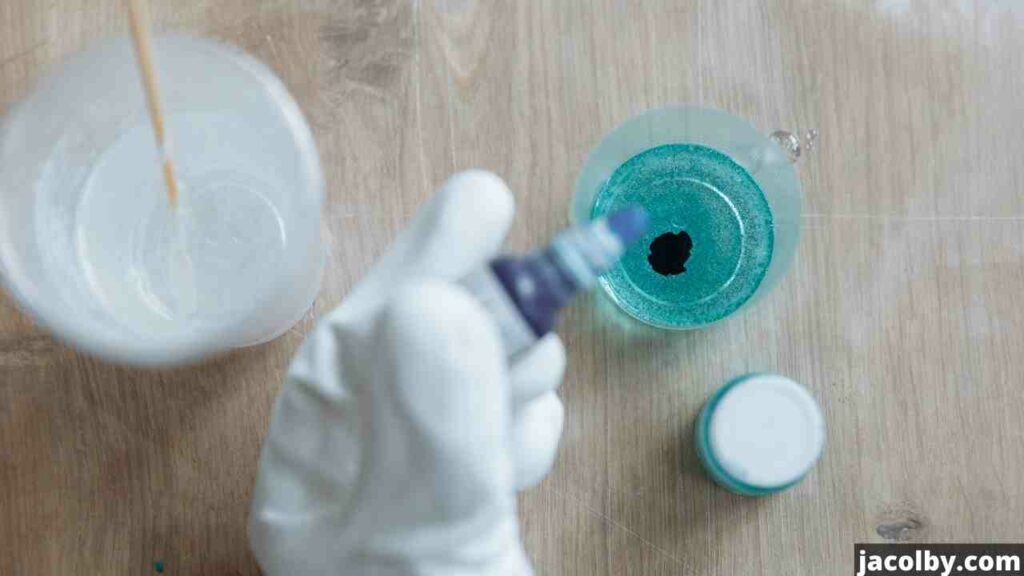

Wear protective clothing and gloves to prevent skin irritation or damage while dealing with the chemicals. Fiberglass resin has the potential to cause severe itching. A first aid kit should be on hand in case someone gets burned.

2. Ensure Adequate Airflow –

Let some fresh air in by cracking the windows and door. Do your best to get your work done somewhere with lots of windows and fresh air. If the space is small and poorly ventilated, even a respirator may not be enough to keep you safe.

3. Make use of glass-reinforced plastic cloth –

A robust patch repair cannot be achieved with only fiberglass resin. Apply all available patches at all times. The resin and cloth should be used to reinforce the region that needs fixing or resealing.

Bonding is the sole function served by the resin. The fabric gives the patch the necessary reinforcement.

Epoxy Resin –

1. Take care of your eyes and vision –

- Protect your eyes with safety glasses or goggles to avoid getting resin, hardeners, mixed epoxy, or sanding dust in your eyes.

- You should immediately run low-pressure water into your eyes for 15 minutes if you get epoxy in them. Get some help from a doctor.

2. Take Care of Your Lungs and Throat –

- Keep your lungs clear of sanding dust and epoxy fumes. Even though our epoxies have a low volatile organic content (VOC), vapors may accumulate in closed environments. Small workshops and similar facilities should have enough ventilation.

- Wear a respirator fitted with an organic vapor cartridge while working in an area with poor ventilation.

- Sanding epoxy, particularly uncured or partly cured epoxy, requires enough ventilation and a dust/mist mask or respirator to protect the user’s lungs.

- There is a higher risk of sensitization if you breathe in epoxy dust before it has fully set. The epoxy may take more than two weeks to fully cure at room temperature, even after it has dried to a sandable solid.

3. Epoxy is toxic if ingested.

- Be sure to take extra precautions while eating or smoking after touching epoxy.

- For those unfortunate enough to have ingested epoxy, it is recommended that they drink plenty of water instead of forcing themselves to throw up. Worse, hardeners are caustic and may be harmful if vomited. Get in touch with a medical professional or poison control right away.

FAQs –

On what kinds of substrates does epoxy resin fail to adhere?

A.1 Epoxy resin adhesives are superior for fusing various wood, metal, and glass substrates together. It will not adhere to multiple materials, including Teflon, polyethylene, polypropylene, nylon, and Mylar.

It does not bond very well to polyvinyl chloride, acrylic, or polycarbonate polymers. Experimentation is the only way to assess whether or not an epoxy will adhere to a particular material since there is no other way to do so.

Where does all of the money go to the price of epoxy resin?

A.2 Epoxy often has a higher price tag than resin because of the stringent formulation and strength criteria it imposes. Resin is gaining popularity as a material for manufacturing jewelry and crafts because it is more affordable.

However, it is essential to remember that you get what you pay for in life. Epoxy has high water resistance so certain formulations may be applied underwater under specific circumstances.

Is polyester resin the same thing as fiberglass resin?

A.3 Fiberglass is a specific kind of glass mat that may be purchased in several distinct forms. The resulting substance is known as polyester fiberglass resin when fiberglass mats or cloths are saturated with polyester resin.

Epoxy resin may also be used in this manner; however, polyester resin has been referred to as fiberglass resin for some reason.

Conclusion –

Epoxy is superior to resin glue when it comes to forming solid connections; nonetheless, both types of cement have the potential to be strong.

The length of time required for drying is the primary difference between the two forms of glue. Epoxy and resin are both types of adhesives that must be mixed before use; however, epoxy dries far more quickly than resin glue.